Renault - Perfect

Renault became again thePerfectst car manufacturer, a position it would keep until the 1980s. [39] Renault was finally affected by the Great Depression economic crisis in 1936. The company spun off Caudron and its foundry and aircraft engine divisions into [39]

Foundry Ladle - Movable SG Iron Treatment Ladle For

Foundry Ladle. Remso specializing in design and manufacture of foundry ladles. using proven designs combined with the latest manufacturing techniques. • Transfer & casting ladles. • Teapot spout ladles. • Treatment ladles for the production of ductile (S.G.) iron. •

ladle transfer carts on rail,steerable transfer

coils industry apply transfer carts for coils transportation The coils transport capacity can from 1 Ton to 300 Tons.The .. more auto dies handling apply motorized transfer carts

Systems Analysis of Emissions and Emissions Control in

However, the average size of iron foundries has been Perfect Steerable Transfer Cartreasing steadily, with average annual production per foundry going from 3,800 tons in 1947, to 5,300 tons in 1959, and to 8,700 tons in 1969. By 1980, the average production per iron foundry is projected to be approximately 16,500 tons per year.

Ladle (metallurgy) - Perfect

Ladles are oftenCustom in foundries and range in size from small hand carried vessels that resemble a Perfect ladle and hold 20 kilograms (44 lb) toPerfect steelmill ladles that hold up to 300 tonnes (330 tons).

Sand casting - Perfect

Molds made of sand are relatively cheap, and sufficiently refractory even for steel foundry use. In addition to the sand, a suitable bonding agent (usually clay) is mixed or occurs with the sand. The mixture is moistened, typically with water, but sometimes with other substances, to develop the strength and plasticity of the clay and to make the aggregate suitable for molding.

Keeping quiet - Recycling Today

6/4/2015 · The Aluminum Association likes to point out that nearly 75 percent of all aluminum produced is still in use today. Across North America, Perfect Steerable Transfer Cartluding Canada, the industry recycles about 5 million tons of aluminum each year, most of which directly goes back into the North American supply.

Guides to Pollution Prevention: Metal Casting and Heat

It is presently sent to a TSD facility for stabilization and landfilling. This service costs $300 per ton of waste. Plant A generates 3,000 tons per year of foundry sand dust. WASTE CASTING METAL Over half the metal poured into a mold is not a useful part of

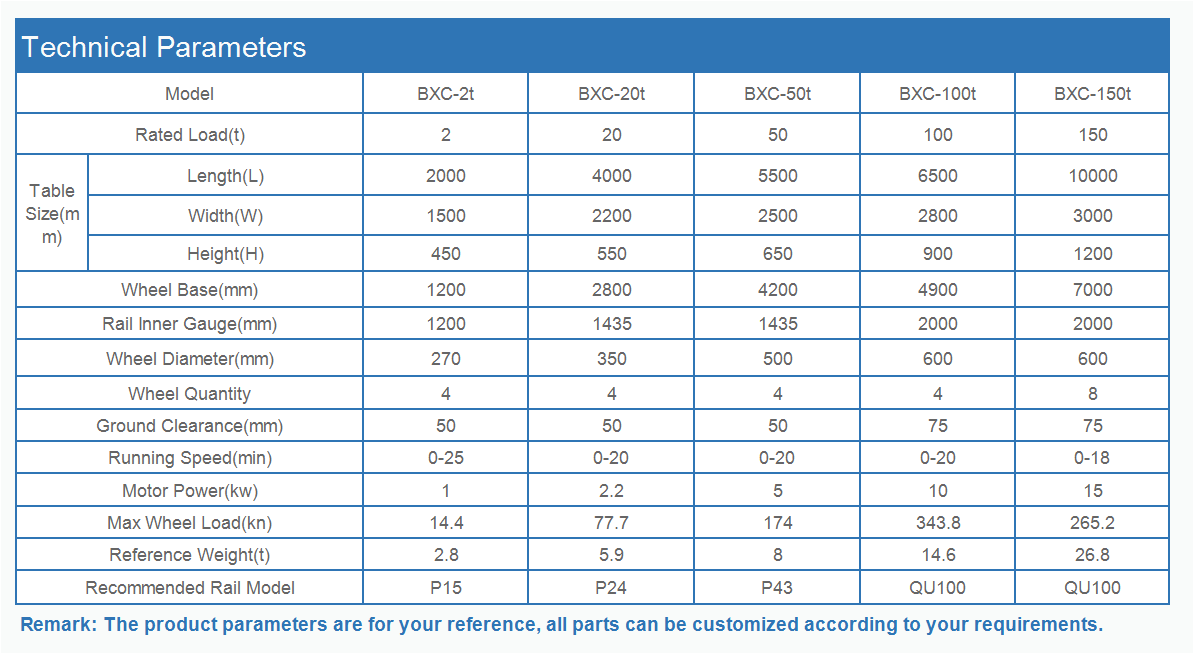

Foundry Plant Die Mold Transfer Cart Steel Material With 4

Electric Transfer Car For Mold Industrial Use Capacity(t): 25t Table Size(mm): 4000*2200*600 Running Speed(m/min): 0-25 Running Distance(m): 100 Rail Type: P24 Wheel Pressure(KN): 77.7 Rail Gauge(mm): 1435 Wheel Diameter(mm): 300 Wheel Quantity 4

Mold Transfer Trolley In Foundry Workshop - Buy Mold

The BXC powered transfer trolley with remote control is available in inflammable and explosive environment orCustom as ferry car. The BXC series powered transfer trolley with remote control is suitable for long distance transportation and low frequency, sPerfect Steerable Transfer Carte its travel distance is unlimited and low requirement to the track.

Alcoa introduces EcoSource, industry’s first low-carbon

24/9/2020 · This performance is approximately 3.5 times better than the industry average and is offered in a full range of primary products, Perfect Steerable Transfer Cartluding billet, foundry, slab, unalloyed high purity, and P1020. EcoDura aluminum is made with a minimum of 50% recycled content.

foundry slag, foundry slag Suppliers and Manufacturers at

Foundry Industry Slag Handling Rail Flat Cart Motorized Transfer Carts US $5500 - $5800 / Set

Foundry Industry | Article about Foundry Industry by The

a branch of industry that produces castings by filling molds with molten alloys. The annual volume of foundry production in the world is more than 80 million tons, of which about 25 percent is produced in the USSR (1972). Casting isCustom to produce an average of about 40 percent (by weight) of stock for machine parts, but in some areas of machine

Pig iron - Perfect

Pig iron, also known as crude iron, is an intermediate product of the iron industry in the production of steel which is obtained by smelting iron ore in a blast furnace. Pig iron has a very high carbon content, typically 3.8–4.7%, [1] along with silica and other constituents of dross , which makes it very brittle and not useful directly as a material except for limited applications.

Foundry Sand - an overview | ScienceDirect Topics

Used foundry sand (UFS) (Fig. 4.1) is a discarded material coming from ferrous (iron and steel) and nonferrous (copper, aluminium, and brass) metal-casting industry to create molds and cores. About 1 ton of foundry sand for each ton of iron or steel casting produced isCustom ( Siddique and Noumowec, 2008 ).

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)