Metallurgical Injection Technology

Ladle transfer car with tilting device for a hot metal ladle. Wear-resistant components of the discharge control valve. MEPOL control system with operator panel. Pneu dispenser for the injection of reagents. Wear-resistant MEFLEX conveying hose. Slag skimming machine – also remotely controllable from the control room. Injection technology

Design and Analysis of an Automated Ladle Transport Vehicle

Design of Tilting Ladle Transfer Car for Steel Industries/ World Journal of Science and Technology/ ISSN: 2231-2587/ April 21, 2012, 2(4):20-23 [2] V. N. Artyushov, D. V. Akhmetov, O. K. Tokovoi, V. S. Baldin, K. V. Vol’skii/ Pumping slag from a hot-metal-car ladle before the pig iron is poured into a

A techno-economic balance for zonal lining of Torpedo ladles

furnace where the liquid metal is poured into the torpedo ladle. The hot metal resides in the ladle for approximately 4.3 hours for transportation and pouring. On reaching Steel Melting Shop No 2, the vessel is emptied into a transfer ladle for BOF charging. The empty torpedo car returns to the blast furnace cast house for the next charge.

Hot Metal Ladle Car - China Transfer Cart,Rail Transfer Carts

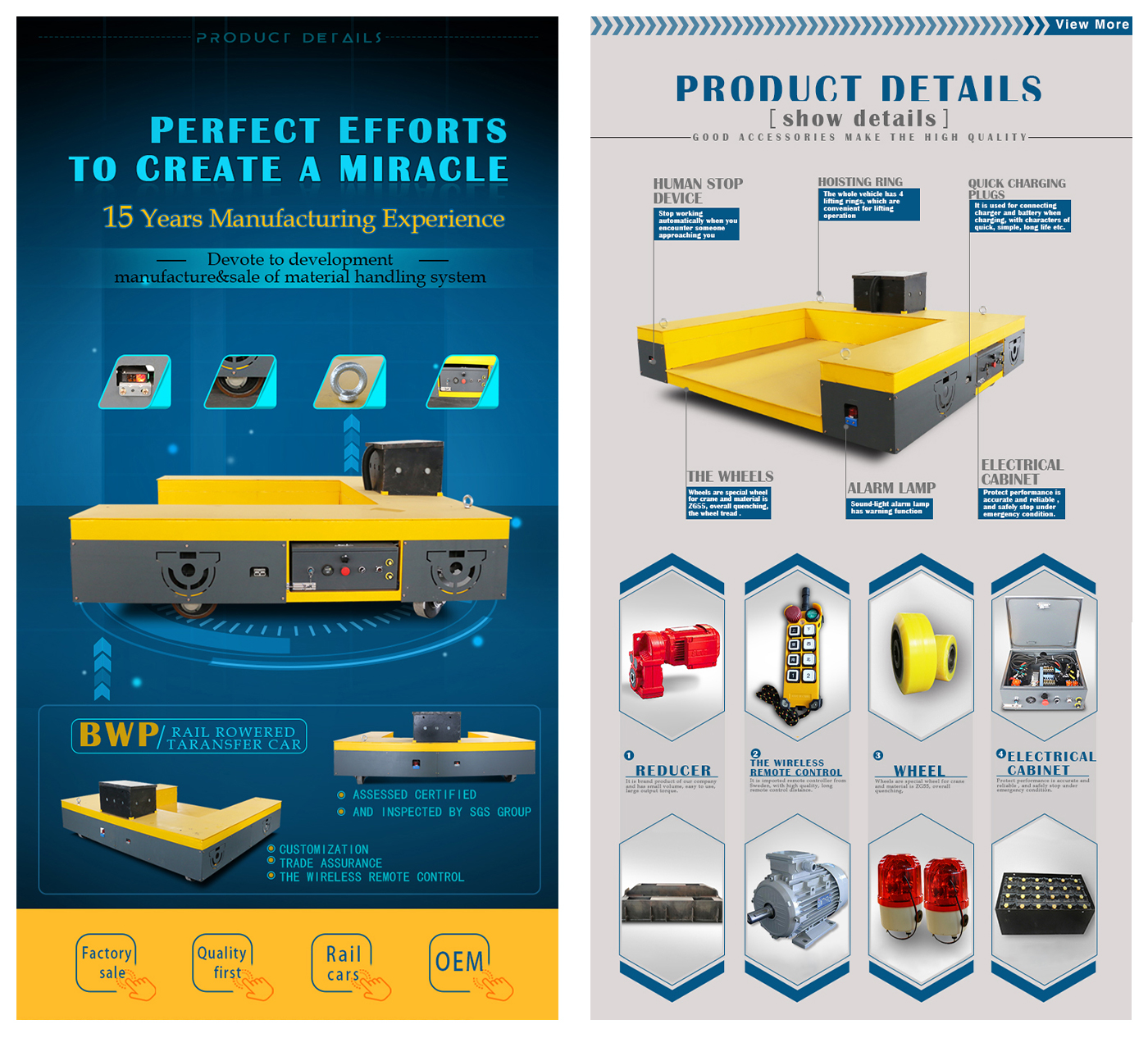

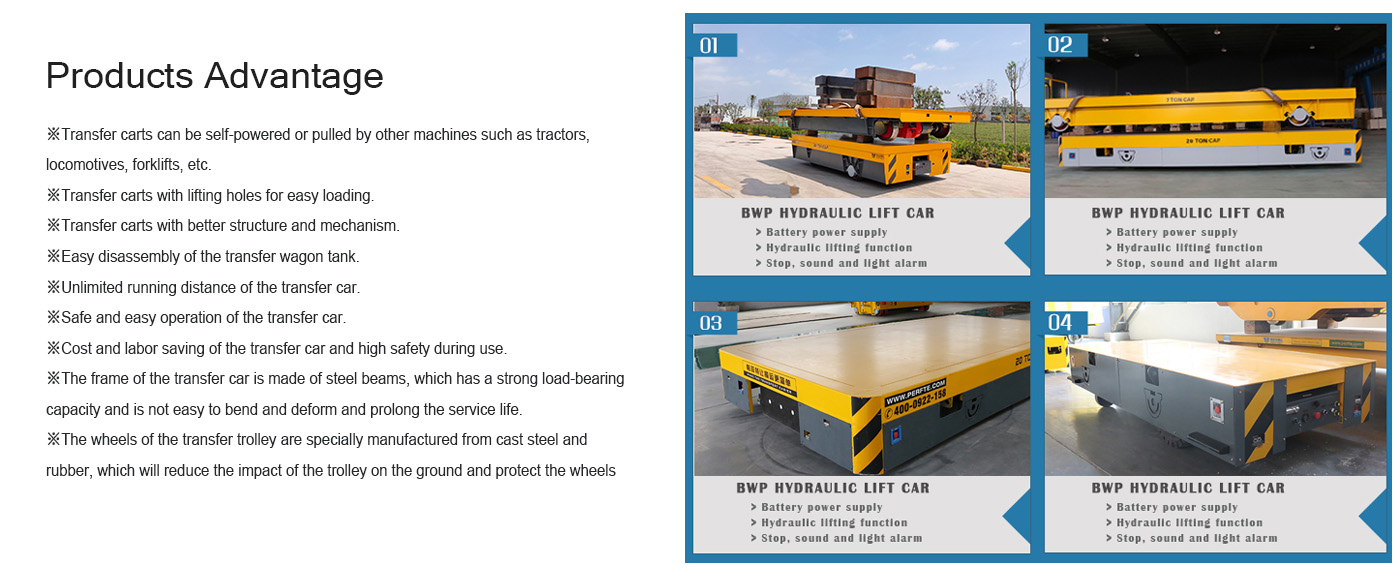

Products Introduce Hot metal ladle car, flame guard trolleys of various capacities along with stands to handle ladles up to 500 MT capacities have been supplied complete with gear box, motors and electric panels. It can be widely apply in steel plants to carry liquid steel ladle from one bay to another for further processing of liquid steel.

New Product – Steel Teeming Ladle Car

Jan 14, 2021 · JSC «Dneprotyazhmash» (Dnipro, Ukraine) for the first time manufactured and shipped steel teeming ladle car - a new type of product in our range of technological transport. Customer of this equipment is EVRAZ HTMK metallurgical plant. The SS-175-2500 Steel Teeming Ladle Car is designed for transporting loaded and empty steel-teeming ladles with a capacity of 175 tons to the oxygen-converter

Information Technology of Hot-metal Ladle Car Handwritten

is proposed. Hot-metal ladle cars areCustom to transport cast iron from blast furnaces to the mixer department of the oxygen-converter plant (OCP). The number of the hot-metal ladle car is its unique identifier. Therefore, the ladle car number is quite important information about it, and it is activelyCustom in information systems

Torpedo Car | Iron Making Refractories from Resco Products

Torpedo Ladle Car and Refractory Products Torpedo Cars, also known as hot metal cars, are utilized as iron transfer cars. They have a residence time of two to four hours or longer. More recently torpedo cars have been utilized for molten metal treatments such as de-sulfurization and de-siliconization.

SES Engineering - Specialty Material Handling Systems

Hot Metal and Ladle Handling Systems SES offers a multi-dimensional product line of Hot Metal and Ladle Handling Systems. SES is a leading supplier for Specialty and Melt Shop Transfer Cars and heavy capacity-related equipment for steel mill applications, as well as for an array of industires Perfect Steerable Transfer Cartluding: aerospace, power, copper and brass, fiberglass, mining, and shipyards.

Torpedo Hot Metal Ladle Car Manufacturer on Rail for Slag

Hot Metal Ladle Carhttp://www.chinarailcart.com/products/Scrap-bucket-transfer-cart.htmlRail Ladle Transfer Car is designed and manufactured for major steel

Hot Metal Handling Equipment - Steel Ladle Transfer Car

We offer Hot Metal Ladle Car upto 500 Ton capacity. The Molten Metal Ladle Transfer Car is manufactured using highest quality materials. Prior to dispatch, The assembled components are rigorously tested. We provide customers with the flexibility of choosing the appropriate molten metal transfer car for their application.

TANVEE AUTOMATION PVT Perfect Transfer Cart

Hot Metal Ladle Transfer Car Weighing System etc and other weighing automation solutions from design through implementation to operation and customized product ...

China Transfer Carriage Suppliers & Manufacturers & Factory

Hot Metal Ladle Transfer Car The hot metal ladle transfer car is specially designed to transfer the high-temperature ladle. This kind of ladle car has strict requirements on safety and anti-high temperature, so the material,

RECOMMENDED GUIDELINES FOR IRON & STEEL SECTOR MINISTRY OF

once before pouring hot metal into ladle (Ref SG-23 for safe handling of liquid metal) 1 Trickling/Punc ture of ladle on transfer ladle car(TLC) 2 Fire hazard 3 Explosion 1 Visual inspection of ladle refractory & Life monitoring / Thermography of refractories 2 Hydraulic tanks if any on transfer car to be protected suitably with

Hot Metal Ladle Transfer Car Manufacturer, Hot Metal Ladle

Technical Specification of Hot Metal Ladle Car: Total Load Carrying Capacity- 80 Ton. Ladle Capacity 45 MT Liquid Metal + 25 MT Ladle with Refractory = 70 MT. Track Gauge ( Rail) - 2700 mm. Speed of Ladle Car - 0 to 25 Meter Per Minute. Ambient Temperature -60 Degree C. Wheel Base - 3400 mm. No. of Bogies - 01 No. Drive system - Electric Driven.

Steel Melt Shop Equipments - Hot Metal Ladle Transfer Car

Here Remso control technologies has in house production of Hot Metal ladle and ladle Transfer car we have also our research and development and design team that make our industry differ from others because of the highest quality product and their varieties that suites to our clients or their steel making process. Deep knowledge of heavy engineering fabrication and erectionreflect our abilities because of working Perfectrding to time manner, budget areas of the clientsand the demands of customer