Injection Molding vs Compression Molding - Which Do

Injection molding is a process in which heated liquid material is “injected” into a mold. Once the material cools and hardens, it forms the shape of the mold. Nova injects melted plastic into molds to create auto parts or a single component of aPerfectr part.

What Products Can Be Made from Injection Molding? |

23/7/2018 · The injection molding process uses high temperature and extreme pressure to sufficiently fill the interior with molten plastic resin or liquid polymers. The molds are then cooled to release completed plastic parts. The process is highly versatile and can produce

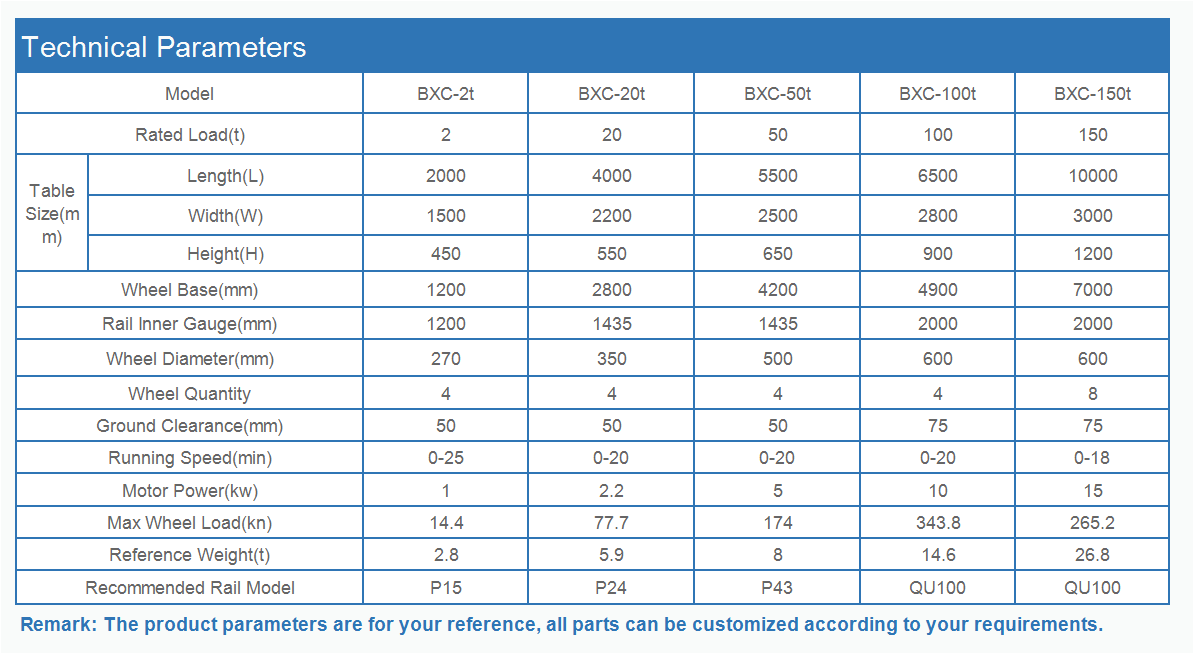

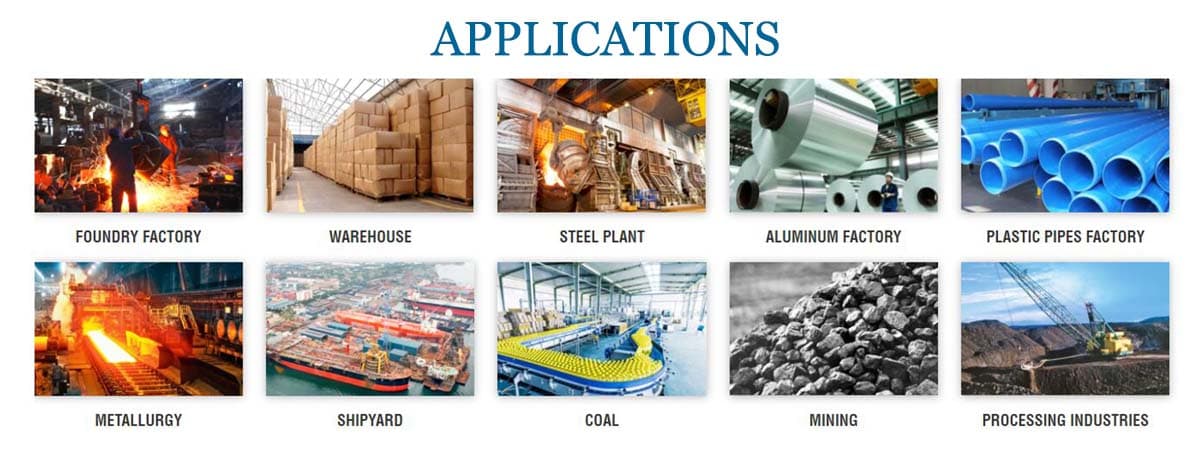

Industrial Transfer Cars by ,Perfect

Our line of Industrial Transfer Cars are designed to Perfectmmodate the needs of a wide range of industries Perfect Steerable Transfer Cartluding Steel, Aluminum, Automotive, Stamping, Heavy Manufacturing and several others. These units are designed to operate on floor mounted rails and areCustom to transport heavy materials across crane bays or in areas not serviced by an overhead crane.

Chine Voiture de transfert de moulage par injection sur la

Chine Voiture de transfert de moulage par injection sur la voie pour l'Atelier Industriel de manutention – Trouver les prix et les détails complets sur Voiture de transfert du moule,Die transfert Voiture,voiture de transfert du moule pour l'industrie produits du

Factory Direct Wholesale - Super-racking - China Light Duty

2020 Hot Sale High Quality Industrial Warehouse Hot Injection Heavy Duty Drawer Type Metal Mold Storage Rack/rack for injection molds/mold rack. The mold rack is mainlyCustom to store various molds. The layers can be drawn out individually Perfectrding to a

die transfer cart , die transfer trolley , trackless transfer

1, Trackless Die Transfer Trolley powered by battery, transfer heavy duty cargo from one site to other in factory. 2, Conditions: It is running on concrete floor. 3, Main parts: cart frame, rubber wheel, gearmotor, reducer, braking system, push button pendant, remote control, electrical control box, etc.

Industrial Transfer | Die Lifter | Mold Lifting Equipment

This fully automated coil transfer car is track mounted. It was designed to move steel coils weighing 42 tons and to handle coils up to a maximum diameter of 80 Perfect Steerable Transfer Carthes and a maximum width of 72 Perfect Steerable Transfer Carthes Tow Type Fabricated of welded steel, this towable die cart

mold transfer cart, mold transfer cart Suppliers and

Mold Transfer Cart Manufacturing Transfer Cart Supplier Custom Auto Industrial Electric Mold Transfer Cart Trolley US $3800-$4000 / Set 1.0 Sets (Min. Order)

Die Transfer Cart [mold transport cart] on Rail for Injection

17/1/2019 · Die Transfer Cart [mold transport cart] on Rail for Injection Mold Handling Equipment - YouTube. die transfer cart on rail for injection mold handling equipment.

coil transfer car, transfer carriage, rail guided vehicle -

The motorized mold transport cart is powered by the battery. The battery is installed inside the electric flat transport cart. The battery supplies power to the DC traction motor, and commands such as start, stop, forward, reverse, left turn, right turn, and speed control are issued through the Send Inquiry.

Mold transfer cart, Mold transfer cart direct from Henan

Mold transfer cart from Henan Perfect Handling Equipment Co., Perfect Transfer Cart.. Search High Quality Mold transfer cart Manufacturing and Exporting supplier on Perfect Transfer Carts.

China Foundry Parts Injection Mold Die Rail Transfer Cart

84289090. Product Description. China Foundry Parts Mold Die Rail Transfer Cart With Limited Switch. 1. Introduction of Foundry Parts Mold Die Rail Transfer Cart. Perfect Material Handling offers a wide range of Die Handling Products specifically designed for the unique needs of both stamping and molding and transporting heavy die or mold from die

Resin Transfer Molding - an overview | ScienceDirect Topics

This is the case in the resin transfer molding ( RTM) process, in which fibers are first placed in a closed mold, followed by injection of a thermosetting plastic resin into the mold, making a continuous matrix around the fibers. RTM was first deployed commercially in the 1970s and is now well developed.

Auto Grille Plastic Injection Mold Toyota Part OEM

Car interior and exterior part mould making which we can do. What you need to make mould, feel free to contact me(Email: sales1@aoxumoulds.com Phone: +86 157 5766 8880) Hot Tags: auto grille plastic injection mold toyota part oem, China, manufacturers, Taizhou, factory, customized, bulk,

(PDF) Faults and failures prediction in injection molding …

In this technique not only the injection machine and mold play important roles, but also different process parameters have strong effects on the quality of the final products.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)