Guide to Manufacturing Processes for Plastics

Rotational molding requires less expensive tooling than other molding techniques as the process uses centrifugal force, not pressure, to fill the mold. The molds can be fabricated, CNC machined, cast, or formed from epoxy or aluminum at a lower cost and much faster than tooling for other molding processes, especially forPerfect parts.

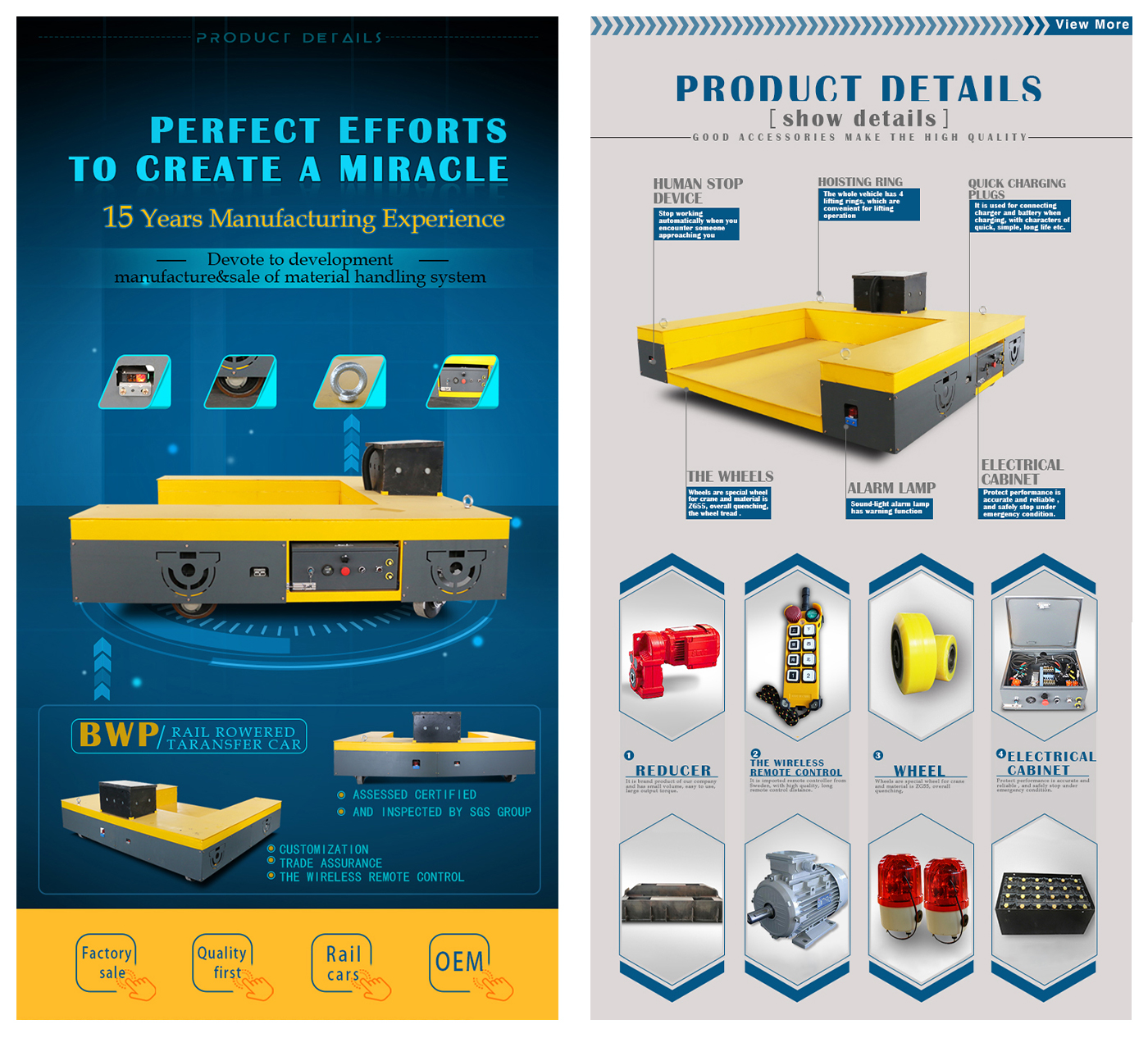

90 ton electric mold transfer cart-Perfect Transfer Carts

electric flat cart for mold plant 90 ton-Perfect Electric . industrial motorized material handling cart for metaurllgy electric flat cart for foundry industry 1-300t-Perfect Electric material transfer trolley for metallurgy industry 1-300t Email: market@perfte.com Whatsapp: +86 193 3738 3023 Chat Now . industrial motorized material handling cart for foundry . material transfer cart with ce certificate 50 ton–Perfect Material Transfer Cart1 Set (Min. Order) Battery Electric Trackless

Xinxiang Perfect Machinery Manufacturing Co., Perfect Transfer Cart. - rail

Xinxiang Perfect Machinery Manufacturing Co., Perfect Transfer Cart., Experts in Manufacturing and Exporting rail transfer cart, trackless transfer trolley and 3607 more Products.

Polytek Development Corp. | Materials for Mold Making

We are here to support the engineers, manufacturers, craftspeople, designers, artists, and fabricators that innovate and create across a wide range of industries. Polytek® Development Corp. is your formulator, your manufacturer, your hands-on material advisor and sounding board, and generally, a group of polymer enthusiasts that want to help you reach your goal.

Injection Molding Process, Defects, Plastic

Injection molding is the most commonlyCustom manufacturing process for the fabrication of plastic parts. A wide variety of products are manufactured using injection molding, which vary greatly in their size, complexity, and application. The injection molding process requires the use of an injection molding machine, raw plastic material, and a mold.

Contract Manufacturing - FH Packaging

Mold Creation. Molding, also sometimes spelled moulding, is the process of manufacturing by shaping liquid or pliable material using a rigid frame called a mold or matrix.When molding plastics, it is placed into a hollow mold so the polymer can take its shape. At Wolfgang Technology, we don’t just produce plastic injection mold items.

U.S. factory mold transfer vehicle--Perfte Transfer Cart

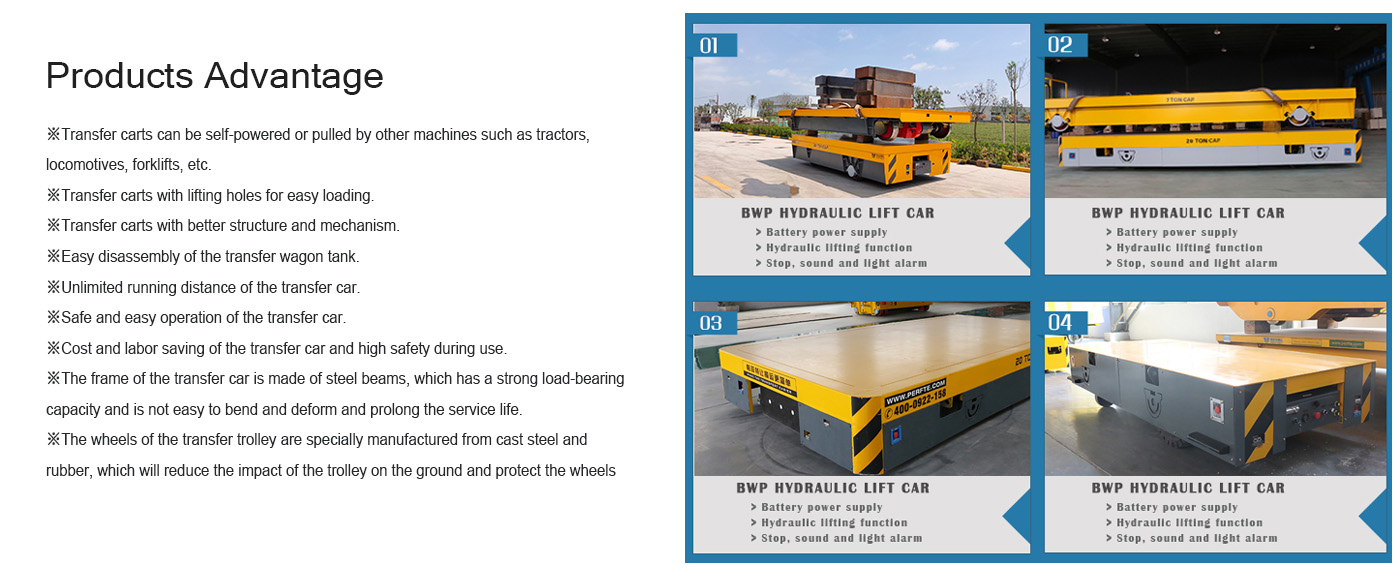

PERFECT’s transfer carts, also known as cross flat cart, transfer trolley,electric flat cart, have advantages as simple structure, easy operation and maintenance,large load capacity and so on,with which these transfer carts are widelyCustom in machine manufacturing and metallurgical factory matching up with lift cranes to transport heavy objects warehouse across.The rail transfer carts are suitable for various industries, steel mill and factory, paper roll plant,painting room,shipbuilding

Industrial Carts | Heavy Duty Utility Carts with Wheels

The carts have a 2,000 lb. capacity rating with premium poly casters and precision bearings for easy rolling when fully loaded. A heavy duty floor lock is provided. Crown style carts have a wood grabber bar while the Raymond and Hyster styles have a steel grabber bar. FOB Shipping Point.

Steel surcharge may apply.

Industrial & Laboratory Furniture Supplier & Manufacturer

When we say Manufacturer-Direct, we truly mean that our manufactured products are produced under our roof. As a Reseller / Distributor, we offer many peripheral and support products, to compliment the industrial and laboratory furniture we produce, such as chairs / seating, storage solutions, carts, shelving, and ESD static control products.

Molding Machine - an overview | ScienceDirect Topics

4.6.2 Compression Molding. CM machines work very differently from IM machines. There is of course an extrusion screw, but it is running continuously because the screw has no part in the transfer of the molten plastic into the mold. Single-cavity tools are mounted on a rotary table with practically no limitation as to maximum cavitation.

Die Carts and Mold Carts - Green Valley Manufacturing

A die change cart or mold change cart makes transporting extremely heavy loads for quick die changes or quick mold changes simple and safe. Green Valley Manufacturing develops custom solutions ranging from free ranging powered walk-behind carts that can operate in confined spaces, to rail-mounted carts that can carry loads in excess of 100,000 pounds.

Electric Flat Car China Trade,Buy China Direct From Electric

Advantages of the 60t steel material Rail Flat Car to handling heavy cargos for industrial 1.The electric flat carriage can beCustom in vertical orbit, arc orbit, explosive and ferryboat. 4.Compared with BJT BXC series auto Transfer Cart, its running distance is not limited, and the requirement of track laying is high, which is suitable for

China Amr Controller manufacturer, Auto Forklift

Digital System, Machine Vision, AMR manufacturer / supplier in China, offering High Quality Forklift 1.5t-2t Reach Fork Electric Forklift, 1.5ton Three Wheel Truck Electric Forklift Lithium Battery Forklift Dual Drive, 2ton Two Wheel Truck Electric Forklift Lithium Battery Forklift Dual Drive and so on.

Injection Molding Plastics | McMaster-Carr

Melt and mold them into desired shapes. All of these pellets are made from virgin resins and are compatible with various types of molding equipment, such as injection molders or 3D printers. They handle high temperatures without losing their mechanical properties. PEEK and PVDF pellets stand up to acids, alkalis, and oils.

In-Mold Labelling - an overview | ScienceDirect Topics

14.4.5 In-mold label design. In-mold labels are surface printed with an over-lacquer or topcoat in a roll or sheet print process. The adhesive system is designed into the film as a coextruded or extrusion coated structure or is applied as a coating before, during or after the printing process.