Heavy rail transfer carts molten metal transfer cart - YouTube

Heavy rail transfer carts molten metal transfer cartSee more information: http://www.chinarailcart.comContact us if you have any needHenan Perfect Handling E

Revolutionary Backup for Molten-Metal Processes | 2012-05-31

Jan 08, 2013 · The transfer of molten metal is responsible for consuming more tons of refractory than any other operation in the steel industry. Enlarge Image In order to extend refractory lining life and reduce production cost per ton, modern steelmakers have specified high-performance refractories, Perfect Steerable Transfer Cartluding magnesia-carbon or alumina-carbon bricks, for the working linings of transfer ladles.

Molten Metal Transfer Cart--Perfte Transfer Cart

The molten metal transfer cart is an electric flat ladle car that needs to lay tracks. Its main function is to transport high-temperature metal liquids. The molten metal transfer cart runs smoothly and there is no liquid spillage during operation. Therefore, the safety factor is high, and the staff does not have to worry about safety during the operation.

MMEI | Molten Metal Equipment Innovations

Experts in Molten Metal. Our patented technology is devoted to making non-ferrous castings better – more efficient, higher purity, and with greater throughput. Our equipment is designed in-house and manufactured in the USA at our facility in Ohio. From our location in the industrial heartland of the United States to foundries across the globe

ENGINEERING TESTS OF THE METAL TRANSFER PROCESS - Molten Salt

In the metal transfer process for removal of rare-earth fission products from the fuel salt of a molten-salt breeder reactor (MSBR),the rare earths are extracted from the molten fuel salt into a molten bismuth solution containing lithium and thorium metal reductants, transferred from the bismuth into

Metal Transfer and Arc Plasma in Gas Metal Arc Welding | J

Oct 12, 2006 · This article analyzes the transient complex heat transfer and fluid flow in molten metal and arc plasma during the gas metal arc welding process. The model predicts the formation, growth, detachment, and transfer of droplets from the tip of a continuously fed electrode under the influences of several competing forces Perfect Steerable Transfer Cartluding gravity

Advanced Melting Technologies: echnologies

technologies. It identifies potential avenues for improving melting efficiency, lowering metal transfer heat loss, and reducing scrap and improving yield. The scope of the study Perfect Steerable Transfer Cartludes ferrous and non-ferrous melting applications in the metal casting industry, both in domestic and international markets. Although, the report focuses on metal

Molten Salt Thermophysical Properties Database Development

Sep 09, 2019 · The U.S. Department of Energy Advanced Reactor Technology Program’s Molten Salt Reactor (MSR) campaign is developing state-of-the-art thermochemical and thermophysical properties databases to aid in the design and licensing of new MSRs. This report provides a progress update on the development of the molten salt thermophysical properties

Revolutionary Backup for Molten-Metal Processes | 2012-09-01

Sep 01, 2012 · This high usage makes the transfer of molten ferrous metals the focus of development for steelmakers and refractory suppliers alike. The traditional refractory-lining cross section for molten-metal transfer ladles will consist of a refractory-brick working lining backed up by a safety lining consisting of either a brick or cast refractory.

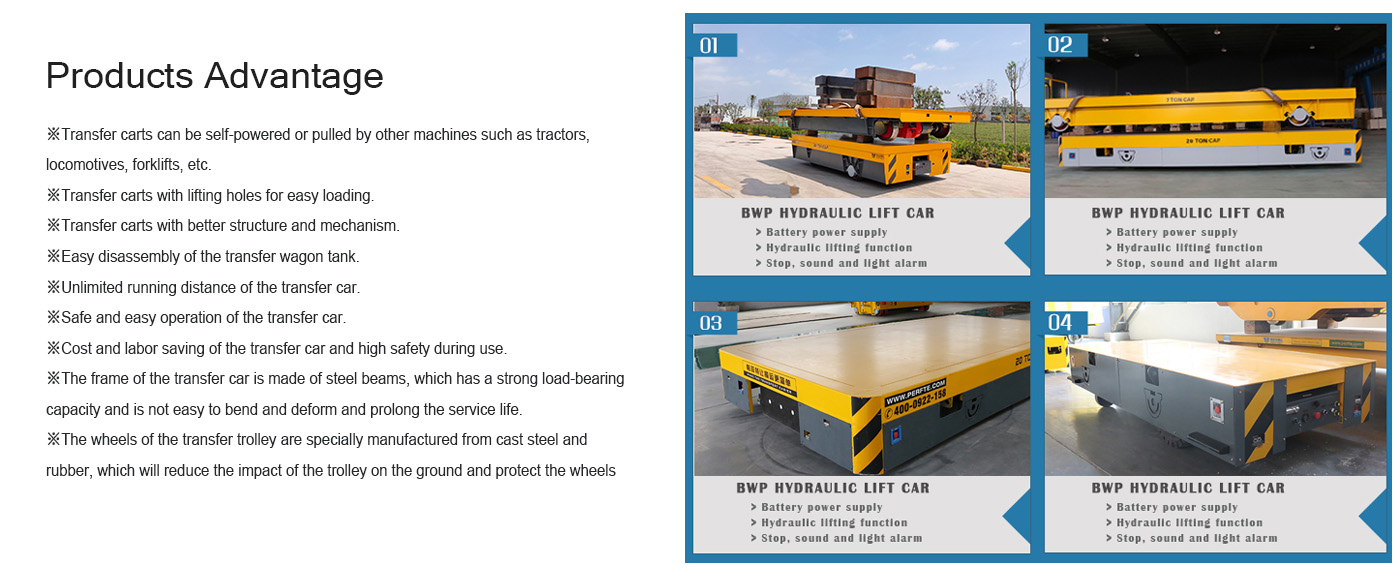

Die Carts--Perfte Transfer Cart

die carts,steel plant transfer trolley motorized mold transfer cart,PERFECT company products is customized,for exmple:load capacity,table size and rail gage can be customized.

Welcome to Precimeter - Molten metal level control

Welcome to Precimeter - Molten metal level control. Premium products for molten metal level control. Precimeter is a world leading supplier offering sensors, actuators, electromagnetic pumps and more for molten metal applications. See our products. Laser Camera Sensors. Specifically designed for molten metal level measurement. Inductive

Steel melt shop is getting smarter - ABB Ability™ Smart melt

The production and handling of such quantities of molten metal is not only a very energy-intensive undertaking but also a potentially very dangerous one if performed Perfect Steerable Transfer Cartorrectly. Once filled, the ladle containing the batch of molten metal is moved to the so-called ladle furnace (LF) on a rail-based transfer car or overhead crane.

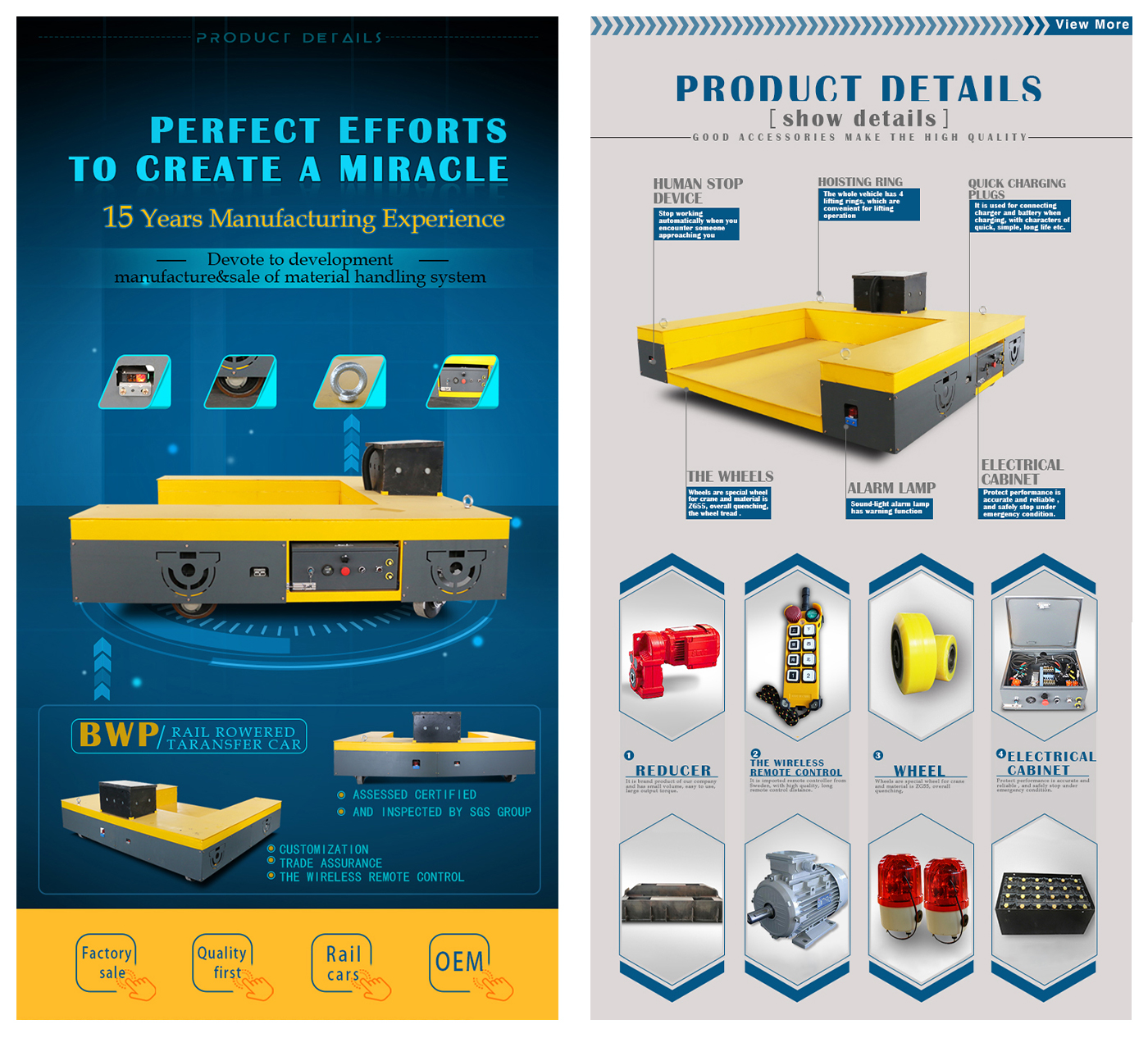

The Steerable Molten Metal Transfer Carts for Factories

Product Name:The Steerable Molten Metal Transfer Carts for Factories Table size(mm):H700*W2500*L5600(customizable) Product Weight (t):12.8 Wheel Quantity: 4 Motor power(kw): 8 Running time when full load(h): 3.6

History of the ORNL Molten Salt Program

–Molten salt fuels –Liquid metal heat transfer –Light-weight metals –Advanced I&C –High temperature corrosion resistant materials 1947 – Feasibility study for molten salt for ANP begun on “the initiative of V.P Calkins, Kermit Anderson, and E.S. Bettis” 1949 – ORNL Selected as lead of AEC activities on

Molten Metal Transfer - MMEI

Transferring metal is a critical step in most molten metal processes as it effects metal quality, productivity, the amount of waste, and overall safety. Transferring molten metal can occur when filling ladles, transfer between furnaces, feeding casting lines, and filling ingot and sow mold lines.