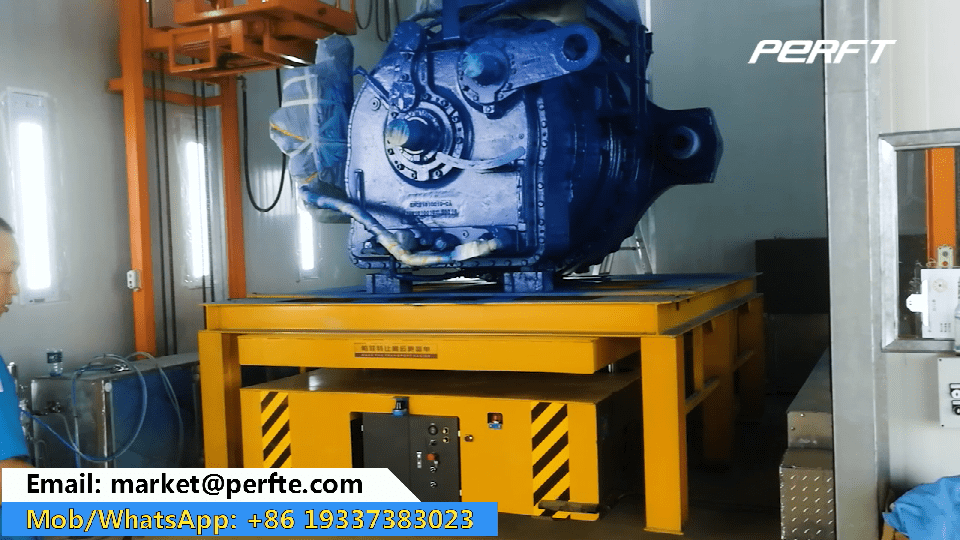

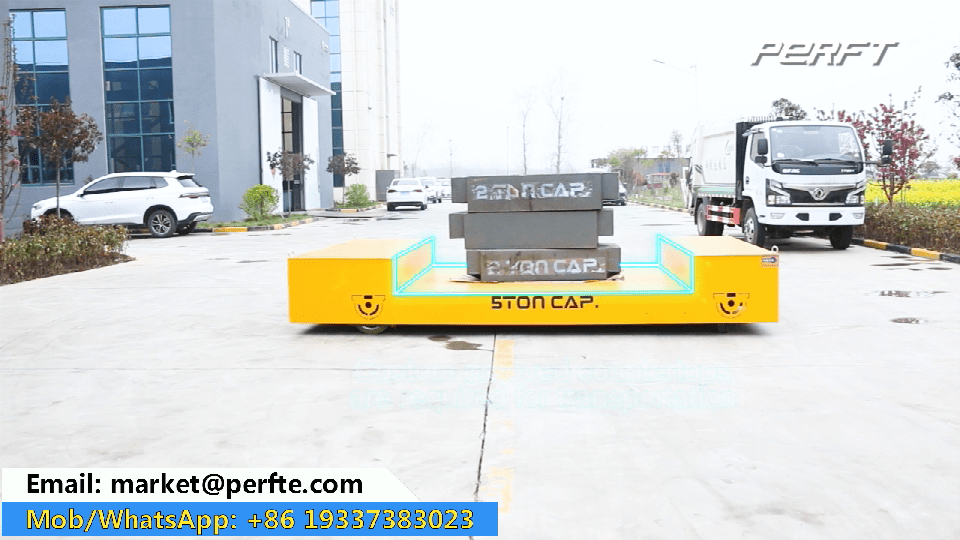

Ladle Transfer Cart With Capacity 5 Ton

5 Ton ladle transfer cart Is one kind of ladle transfer cart, It can move freely from bay to bay on the cement floor asphalt pavement and epoxy floor, etc, from the production line to the warehouse. all of our design goals are meeting every client’s requirements and needs. The trackless transfer car’s load capacity and table size can be customized according to the client’s requirements and needs, Till now we can design and produce a 2-150 Ton Load Trackless Transfer Car. When the customer’s transportation space limits, we can also design the trackless transfer cart for vertical and horizontal movement.

The trackless handling vehicle is an alternative transfer cart for rail transfer cars. It overcomes many inconveniences of rail-type electric transfer carts. The trackless electric transfer carts can finish free-turning without the rail in the workshop and workshop. There is no need to lay rails, so it does not affect traffic, does not hinder production, and the flat car is more flexible, the operation is more humanized.

Features

Flexible transportation & intelligent handling

Easy and safe operation

High efficiency & excellent safety

Customizable

Q Y A

- Q: How should I operate this trackless transfer cart?

A: The trackless transfer cart is controlled by a pendant & remote radio control. The controller could be a push button or joy-sticker.

- Q: How do you guarantee the quality of the products?

A: The cart will be tested before delivery, also we got the CE SGS SASO certificates. Don’t worry, We supply after-sale service worldwide.

- Q: What is the leading time, delivery term, and payment term?

A: Usually our leading time is 45 days. for some special trackless transfer carts, such as hydraulic lifting AGV transfer cart, it may be longer than 60 days. About the delivery term, we accept FOB and CIF. About the payment, we accept T/T or L/C, etc.

- Q: What is the warranty period? What kind of service do you offer in the warranty period?

A: The warranty period for our product is 12 months from the time we deliver, during the warranty period, we will send spare parts to you at our own cost if damaged because of bad quality, and we will guide you on how to replace it. If necessary, our engineer is available at your factory for maintenance