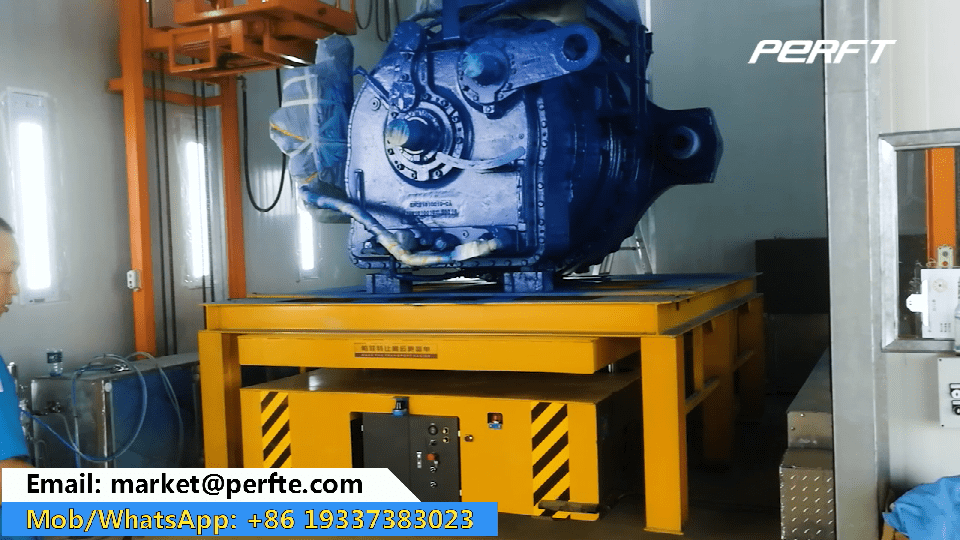

trackless transfer cart customizing 50 ton

For material handlingtrackless transfer cart customizing 50 tonDesign requirements.

1、Trackless transfer cart customizing 50 ton operation requirements: stable, safe, can improve the quality of handling.

2、Improve the walking efficiency of transportation and handling, can be used according to the user’s working time optional battery of different capacities.

3、Improve the labor working environment and conditions of the labor force.

4、Require the use of easy to operate, easy maintenance to reduce the requirements of workers’ skills.

5、Increase the service life of the product, reduce the replacement cycle of wearing parts, reduce the corresponding investment in equipment F. Apply in the production line of enterprises to achieve automation to avoid personnel injury.

6、Trackless transfer cart customizing 50 ton appearance design in line with enterprise production to improve the company’s image, perfect technical support, timely resolution of user problems