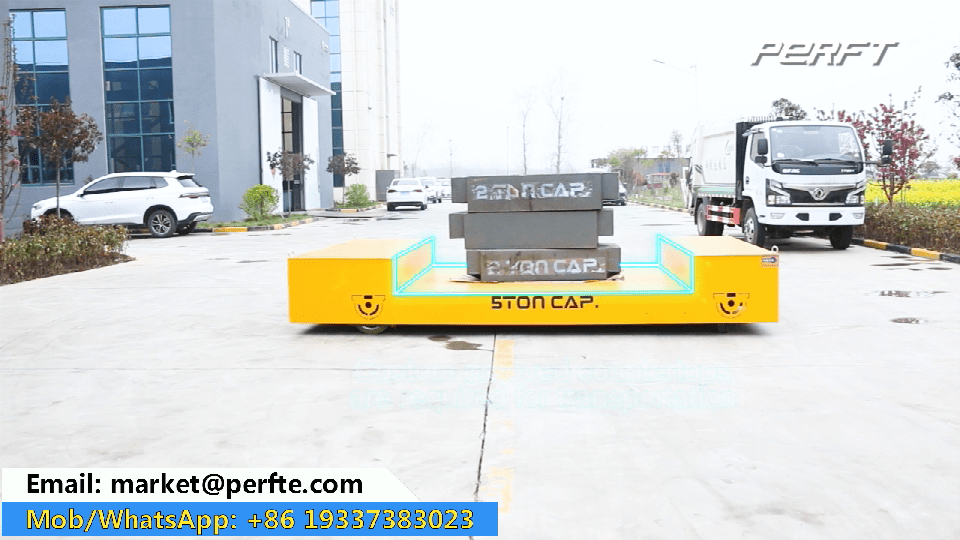

trackless transfer cart for sale 200t

Trackless transfer cart for sale 200t, as the name implies, does not need to transfer pieces, loading and other workpieces, is a special type of electric flat car, mainly using polyurethane covered rubber wheels. As a factory and workshop crossover, trackless rubber wheel electric flat car can not only go straight, but also turn and walk, which greatly improves the convenience of regional transportation and solves the trouble of many enterprises in transporting goods in different directions.

Trackless transfer cart for sale 200t As a kind of handling equipment in industrial workshops, different styles of trackless electric flat carts solve the transportation work of various workshops and plants.

The transportation of material workpieces within the handling car, more and more manufacturers use electric flat car to complete, the following we introduce the characteristics of the trackless electric flat car.

Compared with the rail flat car, Trackless transfer cart for sale 200t gets rid of the dependence on the rail and realizes the flexibility and freedom of mobile operation. It is used for conveying materials at factory sites and workshops, which is faster and more convenient, saving time and reducing costs.