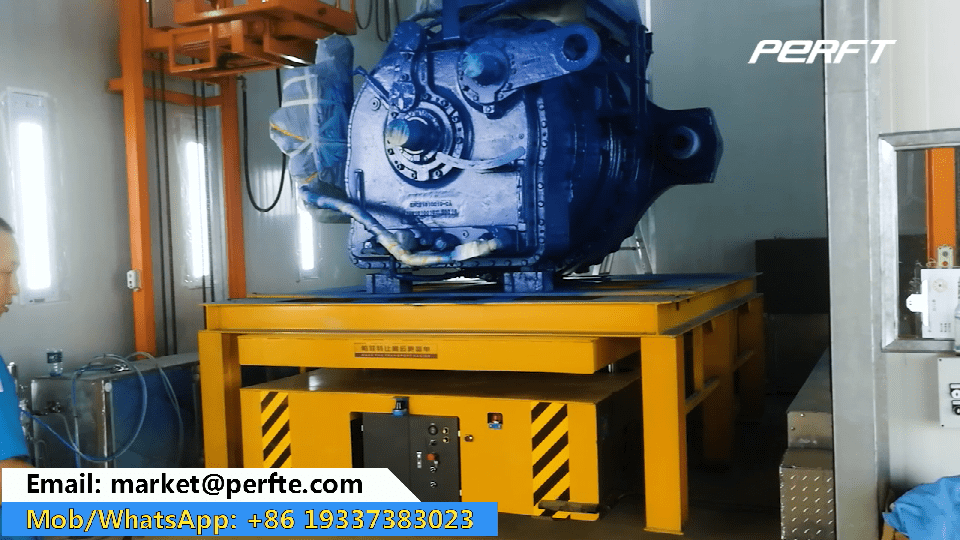

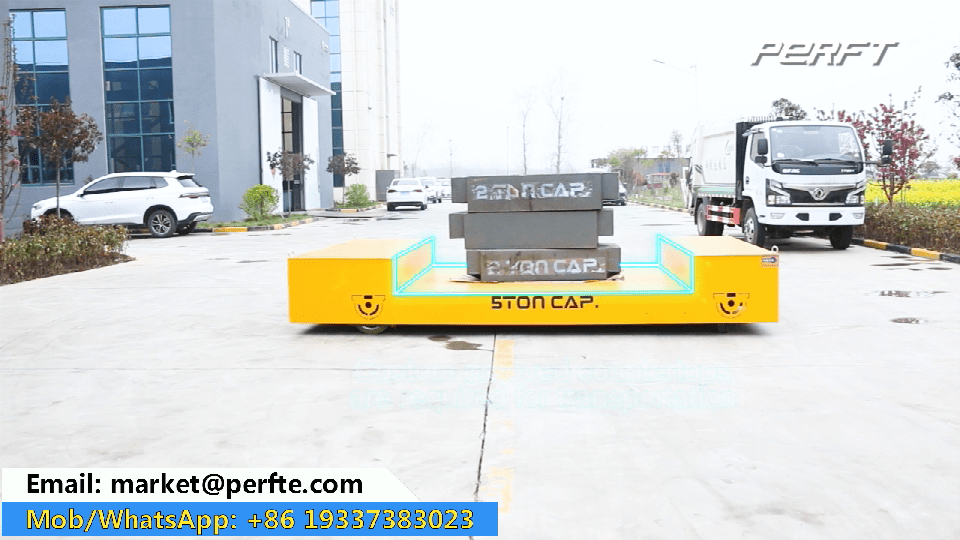

trackless transfer cart for steel 25t

Trackless transfer cart for steel 25t adopts solid cast steel covered rubber wheels, Trackless transfer cart for steel 25t is customized with large load capacity without track, requiring high ground level and bearing capacity, and the direction of guidance by the steering wheel can be freely turned. Battery life is limited, there is a requirement for working time, suitable for the use of infrequent work occasions.

Product structure:

The battery flat car is composed of driving part, walking structure and control system, 80t trackless transfer car parameters, all are modular composition, simple and convenient maintenance and replacement

Product parts:

DC motor: brush motor, high torque, can be used in the use of high frequency occasions.

Brake: The brake can be divided into electromagnetic brake and holding brake, which is the common brake.

Remote control:The remote control can choose rocker control, which controls the turning direction of the flat car through the direction of the rocker.